The construction of any large infrastructure project requires a strong foundation, especially one with the longest main span of any cable-stayed bridge in North America. Recently, the Gordie Howe International Bridge project took critical steps towards the start of construction on the bridge piers with the assembly of test shafts.

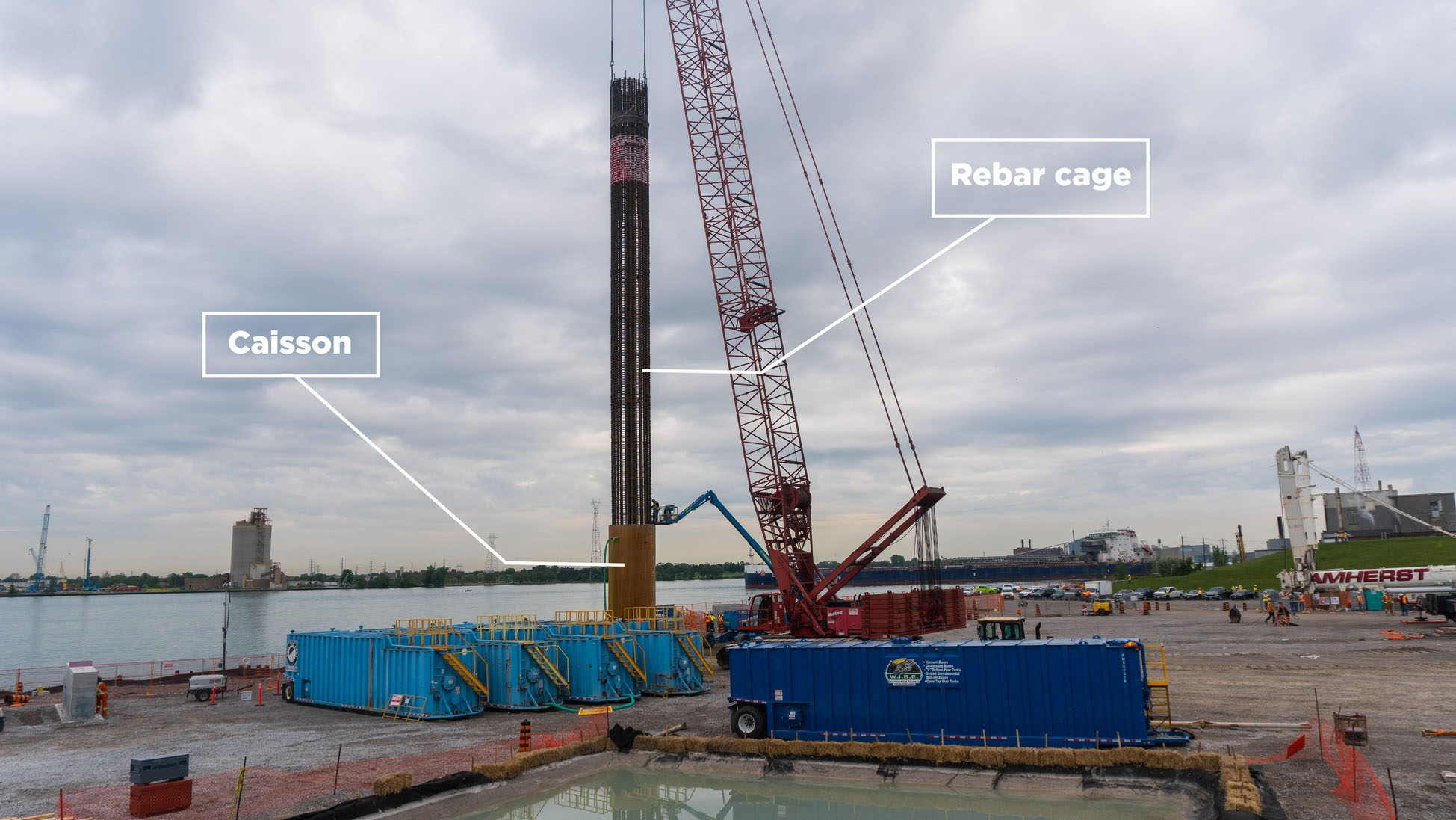

There will be a total of four bridge piers built on land, with each pier supported by six shafts. The first step to building these shafts requires the installation of a caisson. These caissons are drilled to a depth of 37m/121ft, where a rebar cage is eventually inserted into the caisson, and later filled with concrete creating what is referred to as a production shaft.

‘Rebar, or reinforcing steel, is a steel bar used as a tension device in reinforced concrete structures to strengthen and aid the concrete under tension.

The test shaft has two different purposes in the actual construction of the production shafts. First, it is used to verify the design for the ‘production’ version of shafts that will be drilled. Secondly, it helps verify the techniques used to produce the permanent shafts which will form the foundation supporting the main pylon, or tower of the bridge.

The test shaft has two different purposes in the actual construction of the production shafts. First, it is used to verify the design for the ‘production’ version of shafts that will be drilled. Secondly, it helps verify the techniques used to produce the permanent shafts which will form the foundation supporting the main pylon, or tower of the bridge.

Learn more about the installation of the test shaft here: https://www.youtube.com/watch?v=rb1h-n8CQxI