The Gordie Howe International Bridge tower legs, also known as the lower pylon, are about to become one, giving each tower the distinctive shape of an inverted “Y”.

“It is an exciting time as the towers – arguably the most visible aspect of construction to date – move into the next and final build phase,” says Bryce Phillips, the CEO of Windsor-Detroit Bridge Authority (WDBA). “With the towers currently standing at over two-thirds of their final 220 metres/722 feet height, they represent the significant progress the project team has been able to achieve.”

It’s a major step in the construction of the massive towers located on each side of the Detroit River and will allow crews to work on the top portion of the tower, also known as the pylon head.

The process to transition from the lower pylon to the pylon head, anticipated to be completed in the spring, involves modifications to the jump form systems. The jump forms have encased the tower legs to provide workers with an enclosed environment. The exterior of these jump forms provided the perfect canvases for murals that were painted by artists from Walpole Island First Nation, Caldwell First Nation and Southwest Detroit. The murals, which can be seen by travellers on local streets and the Detroit River, feature the Canadian maple leaf and the American stars and stripes and visual stories about the culture and diversity of the region. Instead of a jump form on each tower leg, they will become one and will continue to provide access for workers as they continue to build up the two massive towers on each side of the border.

Two concrete pours will be completed in the transition area to construct the upper cross beam that will merge the tower legs into a single structure in Canada and the United States. They are being constructed using cast-in-place reinforced concrete. Approximately 182 cubic metres/238 cubic yards of concrete will be used for each tower, first for the soffit slab and then the vertical walls.

“This is a major engineering feat,” proclaims Michael Hatchell, the CEO of Bridging North America (BNA), the private-sector partner responsible for the design, build, financing and operation of the bridge and Ports of Entry. “The joining of the two tower legs will mean we’ve achieved an important milestone for the project. BNA has been able to reach this point in the project safely and efficiently and is extremely pleased with the work of our team.”

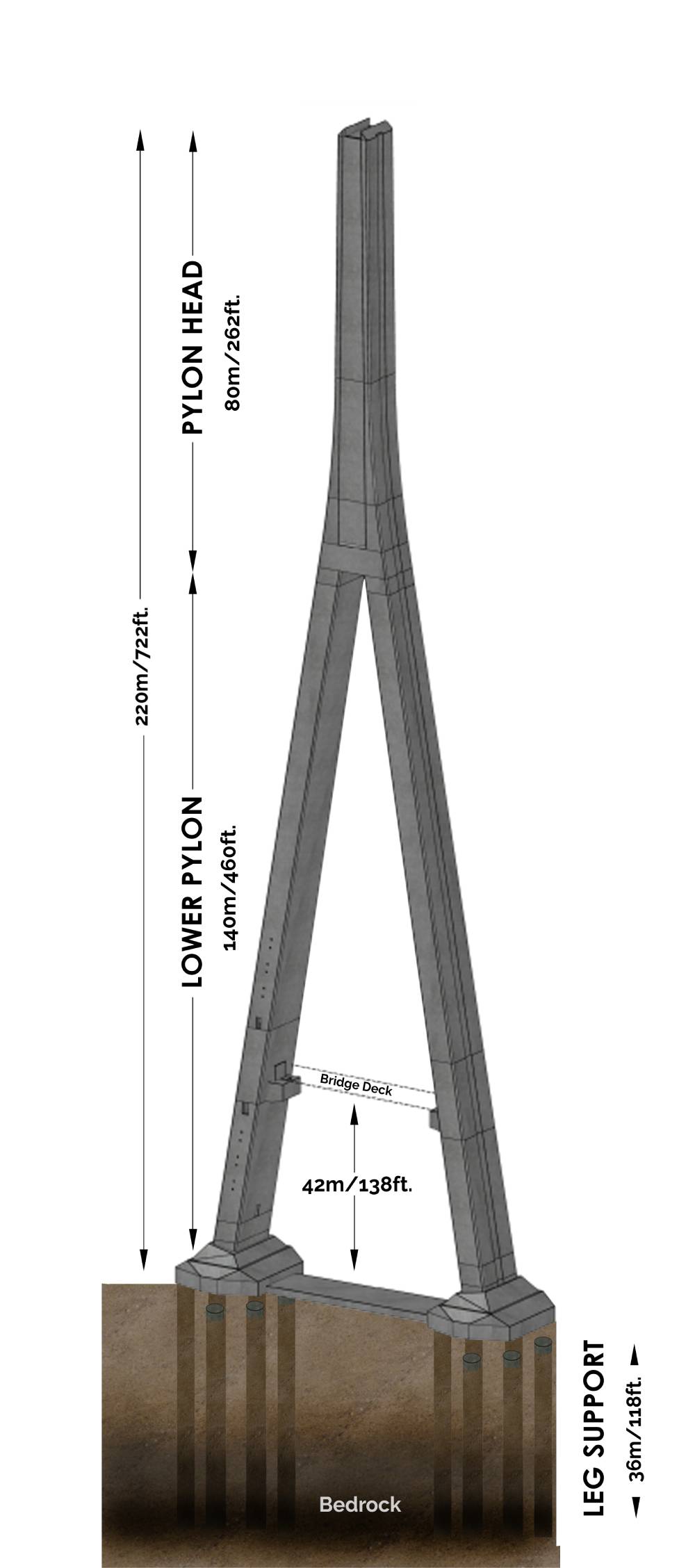

In preparation for the transition work, the tower legs in Canada and the US were built up to nearly 140 metres/460 feet. The lower pylon makes up the longest portion of the bridge towers and is composed of 29 different segments. Each segment has an average height of 4.67 metres/15.3 feet and requires 98 cubic metres/128 cubic yards of concrete and 55 tonnes/121,254 pounds of rebar.

Once the transition work is complete, construction begins on the pylon head. It will measure about 80 metres/262 feet in height. Critical to the cable-stayed design, anchor boxes within the pylon head will house 216 parallel strand stay cables that will connect the towers to the bridge and decks.

The towers have been under construction since 2019. Each bridge tower is made of cast-in-place reinforced concrete and have been built in sequential manner through ‘lifts’ or tower leg segments of approximately 4.67 metres/15.3 feet tall to achieve their aesthetic design and their desired functionality.

“Before you can build up, you have to build down,” adds Phillips. “Substantial work was done underground to help support these massive towers that have become a very visible sign of the project’s progress.”

Each of the towers is supported by twelve shafts drilled into the bedrock to a depth of 36 metres/118 feet -- the equivalent of a 12-storey building. Each of the shafts is filled with approximately 262,000 litres/69,000 gallons of concrete and are connected by 1,600 metres/5,250 feet of post tensioning cables to create a firm footing.

Two tower cranes -- one in Canada and the other in the US -- are being used to build the towers. The cranes have a horizontal jib which can reach 60 metres/197 feet and have a maximum load capacity of 50,000 kilograms/110,000 pounds. As the towers rise in height, so do the cranes. At their maximum height of 244 metres/800 feet, the cranes will be taller than the actual bridge towers.

Once completed, the two towers will soar to approximately 220 metres/722 feet and will rival the height of Detroit’s tallest building, the 73-storey centre tower of the GM Renaissance Center. The full weight of just one tower will be approximately 30,000 metric tonnes/66 million pounds – the weight of 165 jumbo jets. Together, the bridge towers and cable system are being constructed to support nearly 34 million pounds of weight.

- Tower Construction at Gordie Howe International Bridge Entering Next Stage

- Backgrounder - Steps in Gordie Howe International Bridge Tower Construction

- 9 Things to Know About Bridge Towers

- Video: 9 Questions with Kelly Moran, Tower Crane Operator

- Video: Walkway for Tower Construction

By the numbers

At 140 metres/460 feet, the tower legs are already the tallest structures in the City of Windsor and taller than the Statue of Liberty in the US.

Each tower will require 10,000 cubic metres/13,080 cubic yards of concrete and 4,500 metric tons/4,960 tons of steel rebar.

The total weight of the tower legs for each structure in Canada and the United States is approximately 17,500 metric tons/38 million pounds -- or the equivalent of 90-747 jumbo jets.

The tower legs in Canada and the US each required 7,000 cubic metres/9,156 cubic yards of concrete and 2,722 metric tons/3,000 tons of steel rebar.

The tower legs required 58 lifts and the construction was competed in 15 months.

Approximately 182 cubic metres/238 cubic yards of concrete will be used in two separate pours for the upper cross beam.

Together, the bridge towers and cable system will be able to support nearly 34 million pounds of weight.

When complete, the bridge towers will be approximately 220 metres/722 feet tall and will rival the height of the tallest building of the GM Renaissance Center in Detroit.